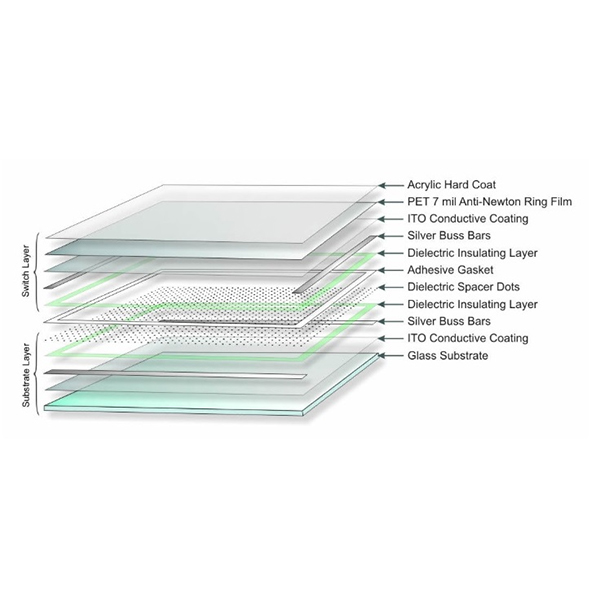

Resistive Touch Screen

Bosic structure For Resitive Touch sereer

|

Available Materials |

|

|

Upper Film |

Single Layer, Double Layers |

|

Clear Film |

Anti-glare(AG) |

|

Anti-newtonring(AN) |

|

|

Anti-reflection(AR) |

|

|

Spacer Dots |

|

|

Glass Substrate |

Ordinary glass,Strengthen Glass |

|

The Upper Film |

|

The Upper Film

Sing Layer/Double Layers Film:In resistive screen projects, single-layer ITO film is generally used. Double-layer ITO film is more convenient for writing, but its price is higher than single-layer film.

Compared to Ag ITO film, celar film has higher clarity and better visual effects. Ag films are not easy to reflect outdoors, making them easier to see. Generally, clear film is used in consumer products, while Ag film is used in industrial control or outdoor products.

Due to structural reasons, ordinary resistive screens are prone to Newton’s rings, which greatly affects the visual effect. On ITO materials, an anti-Newton ring process is added to effectively improve the Newton’s ring phenomenon.

Adding an anti-reflection coating can greatly improve the display effect, making it more transparent and clearer.

The Spacer Dots

The function of spacer dots is to separate the upper ITO film from the lower ITO glass, to prevent the two layers of material from approaching or contacting each other, in order to avoid short circuits and the generation of Newton’s rings. Generally, the larger the size of the touch screen visual window, the larger the diameter and spacing of the spacer dots.

The Glass Substrate

Compared to regular ITO glass, strengthen glass is less likely to break when dropped, meanwhile, the price is higher.